Hydrogen stands out as a promising fuel for the future, offering clean energy potential across transport, industry, and power generation. Yet, efficient hydrogen storage remains a central hurdle to large-scale adoption. From compressed gas storage to advanced metal hydrides, each solution presents distinct advantages and limitations. Understanding these storage methods is essential for anyone interested in energy innovation or tracking hydrogen’s growing role in decarbonizing economies.

What is hydrogen storage?

The term “hydrogen storage” refers to various techniques designed to contain hydrogen safely and practically. Unlike fossil fuels or traditional batteries, hydrogen requires special handling because of its light molecular weight and reactivity.

Also read : Impact of talent shortage on the uk business scene: challenges and opportunities

Effective storage technology ensures safety, meets supply demands, and enables smooth integration into different sectors. Choosing among storage methods involves balancing factors like energy density, infrastructure needs, cost, and usability. This decision shapes both immediate applications and long-term strategies for hydrogen deployment.

Main hydrogen storage methods explained

Researchers and engineers have developed several hydrogen storage solutions, each suited to specific industries and use cases. Generally, these methods fall into two categories: physical containment and chemical approaches based on material absorption or reaction. Below, we examine the main types influencing today’s energy landscape.

Also to read : The impact of brexit on the future prospects for uk small businesses

How does compressed gas storage work?

Compressed gas storage is one of the most widely used methods due to its simplicity and established practices. In this approach, hydrogen is pressurized—sometimes up to 700 bar—in reinforced cylinders or specially engineered storage tanks. High-pressure storage increases the amount of hydrogen stored per unit volume, making it suitable for refueling stations and vehicles.

This method offers benefits such as accessibility and rapid filling, but faces challenges including extra weight, energy loss during compression, and stringent safety requirements. Storage tanks must withstand immense internal pressures, which calls for advanced and often costly materials.

What are the benefits and limits of liquid hydrogen storage?

Liquid hydrogen storage cools hydrogen until it becomes a liquid, typically at temperatures near -253°C. Known as cryogenic storage, this technique allows much higher volumetric density than gas, enabling more energy to be stored in compact spaces. Liquid hydrogen is valuable in aerospace applications and some commercial deliveries, and can simplify long-distance shipping.

However, cryogenic storage requires significant energy to reach and maintain ultra-low temperatures. It also struggles with boil-off losses, where small amounts of hydrogen constantly vaporize, raising pressure inside low-pressure storage vessels over time. Specialized containers help manage these issues, but add complexity and expense. It is worthwhile to explore advanced hydrogen storage options with vallourec for innovations that address some of the limitations in traditional liquid storage systems.

Advanced solid-state storage options

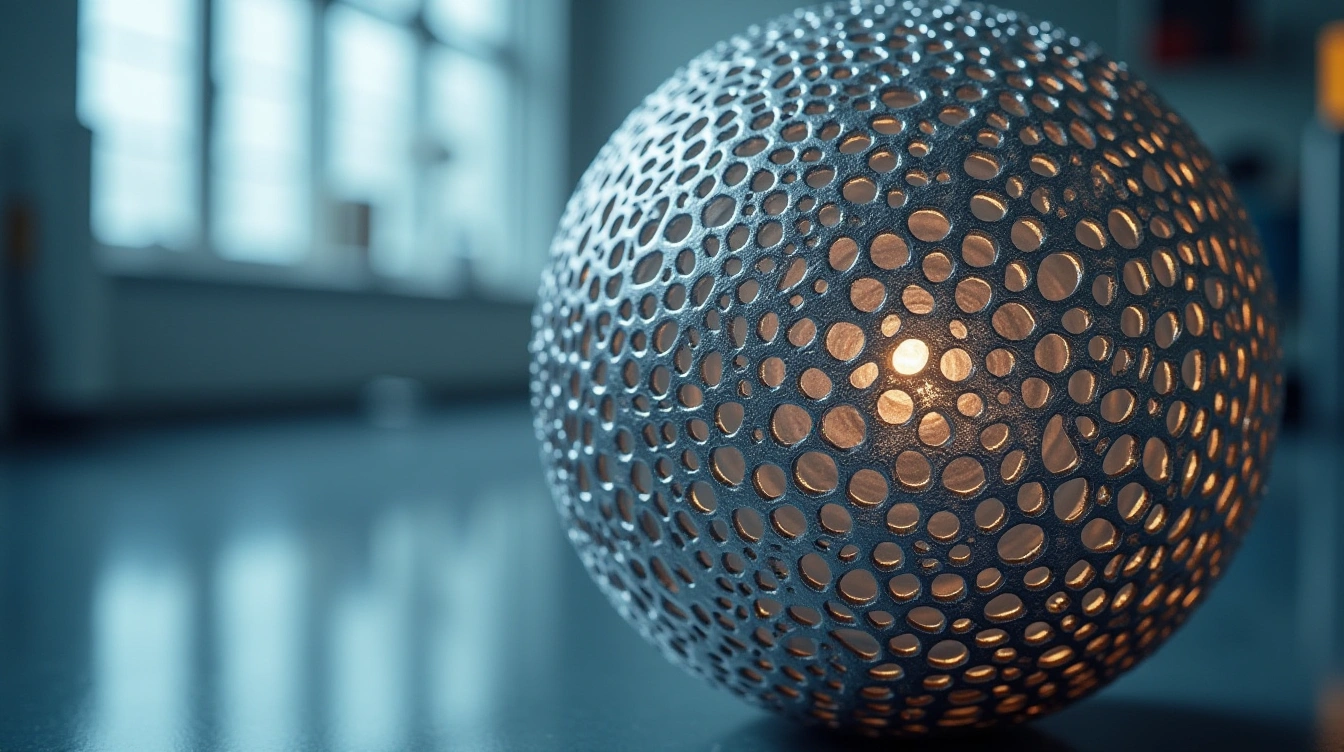

Progress in material science has spurred interest in solid-state storage for hydrogen. Instead of holding hydrogen as a free molecule, these methods integrate hydrogen atoms directly within solid structures. If challenges around efficiency and speed are overcome, this could provide safer and denser alternatives to conventional storage.

How do metal hydrides function as hydrogen stores?

Metal hydrides use metals and alloys that absorb hydrogen under certain conditions to form stable compounds. When conditions change—often through heating—the metal releases the stored hydrogen. This system supports storage at moderate pressures and low temperatures, enhancing safety and compactness compared to high-pressure or cryogenic options.

Drawbacks include slow charging and discharging times, as well as considerable weight from the host metal. Nonetheless, ongoing research seeks new alloys that reduce these disadvantages, potentially expanding the use of metal hydrides in portable and stationary hydrogen storage.

What characterizes other solid-state solutions?

Beyond metal hydrides, researchers are exploring porous materials, chemical sorbents, and complex chemical hydrides. These substances trap hydrogen molecules using weak forces or chemical bonds, sometimes releasing them rapidly when needed. They offer promising avenues for future storage technology, especially if costs decrease and regeneration improves.

While still largely experimental, advances in solid-state storage may deliver greater safety, easier handling, and lower environmental risks than traditional high-pressure storage or cryogenic systems. Success in this area could make hydrogen far more practical for distributed energy needs.

Comparing storage technologies: Advantages and trade-offs

Selecting the right hydrogen storage method depends on factors such as intended use, safety requirements, available space, and budget constraints. Each type brings unique strengths and weaknesses, demanding careful evaluation for every application.

| ⚡ Storage method | 🔋 Energy density | 🛡️ Safety profile | 💰 Cost |

|---|---|---|---|

| Compressed gas storage | Low-moderate | Moderate challenge (high pressure) | Medium |

| Liquid hydrogen storage (cryogenic storage) |

High | Challenging (ultra-cold, boil-off risk) | High |

| Solid-state storage (metal hydrides, others) |

Moderate-high | Fewer hazards | Potentially high (materials cost) |

Physical storage—including compressed and liquid forms—remains dominant in mobile and bulk applications due to scalability and technological maturity. At the same time, innovative solid-state solutions are emerging as competitive choices where weight reduction or enhanced safety is crucial.

- ⛽ Compressed gas storage: Rapid refueling, established infrastructure

- ❄️ Cryogenic storage: Highest volumetric density, demanding maintenance

- 🪨 Solid-state (metal hydrides, porous media): High safety, potential cost savings through innovation

Storage tank design and ongoing research

No matter the chosen method, hydrogen storage tanks must comply with strict international standards for durability, leak resistance, and ease of integration. Manufacturers increasingly focus on lighter materials and modular container designs to boost efficiency and flexibility.

Research efforts prioritize smarter sensors and insulation, along with automated monitoring to address safety concerns proactively. Developers turn to graphite composites and advanced polymers to reduce weight while maintaining strength, facilitating broader use in vehicles and industry.

Key questions around hydrogen storage answered

What are the main hydrogen storage methods?

Hydrogen can be stored using several methods: compressed gas storage, liquid hydrogen storage (cryogenic storage), and solid-state storage. Each method addresses different needs and offers its own advantages and drawbacks.

- ⏱️ Compressed gas storage: Fast refueling, widely adopted

- 🥶 Cryogenic storage: Best for high-density and long-range logistics

- 🔒 Solid-state storage (metal hydrides, sorbents): Enhanced safety, still developing for mass application

How do metal hydrides improve hydrogen storage?

Metal hydrides absorb hydrogen molecules into their structure, allowing storage at lower pressure and temperature than compressed or liquid forms. This generally makes storage and handling safer. Challenges remain, such as slower charge/discharge rates and heavier systems, but ongoing research aims to resolve these issues.

- 🦾 Lower operating pressure improves safety

- ⏳ Charging/discharging is slower compared to gaseous storage

What are the major challenges of cryogenic storage?

Cryogenic storage faces notable obstacles. Achieving extremely low temperatures (-253°C) consumes significant energy, and continuous boil-off leads to hydrogen loss and rising pressure over time. Maintaining specialized storage tanks and ensuring proper insulation increase operational costs.

- ❄️ High refrigeration and insulation requirements

- 📉 Hydrogen loss from boil-off effect

Is high-pressure storage safe for vehicles?

High-pressure storage uses composite-wrapped tanks built to withstand collisions, punctures, and extreme conditions. Strict global standards are enforced, and real-world data indicate strong safety records when protocols are followed. Ongoing improvements in materials and monitoring further enhance safety for automotive and transport uses.

| 🧩 Factor | 🚗 Vehicle storage |

|---|---|

| Pressure rating | Up to 700 bar |

| Tank material | Carbon fiber composites |